BIOREACTOR SKIDS WITH AUTOMATED PROCESS CONTROL

We design and manufacture bioreactor skids that control all the parameters involved in the process of microbial growth, their visualisation, and management through SCADA systems (Supervisory control and data acquisition).

- Jacket for temperature control.

- Acid and base inlet for pH control.

- Sterile gas inlet. These gases can be air, O2, CO2, N2, amongst others.

- Aseptic inlet for inoculum, medium or specific nutrients.

- Ventilation filter. This is usually a 0.2µm hydrophobic membrane to prevent external contamination and emission of cells into the environment.

- Stirrer. There is a variable number and type of blades depending on the culture conditions.

- Probes for parameter analysis (O2 concentration, pH...).

- Aseptic inlet for sampling and parameter analysis.

All these attributes are aimed at maintaining a series of critical conditions in the reactor environment. These conditions are: pH, temperature, nutrients and dissolved oxygen.

OPERATING PRINCIPLES

Our bioreactors are designed to operate in "batch" mode, with the following operating stages:

Loading of the culture medium: Addition of the required volume of medium inside the bioreactor.

Inoculum addition: Addition of the culture inoculum inside the bioreactor.

Bioreaction: The bioreaction is carried out, with temperature, optical density, pH and dissolved oxygen being controlled and monitored.

Bioreactor discharge: The product is discharged for processing in the downstream stages.

CIP: Automated cleaning of the bioreactor, its piping and components.

SIP: Sterilization of the bioreactor.

If a continuous process is needed, our engineering team will carry out the required adaptation.

CHARACTERISTICS OF THE EQUIPMENT

Finishing of surfaces in contact with the product: roughness Ra<0.5 μm, mechanical polishing. Valves in contact with the product: Diaphragm valves with EPDM diaphragms. Designed to minimise the number of connections and welds, dead sections complying with the L < 3D standard, components in contact with the product designed for the pharmaceutical industry.

Support frameAll components, including the bioreactor, are supported on a 304L stainless steel frame.

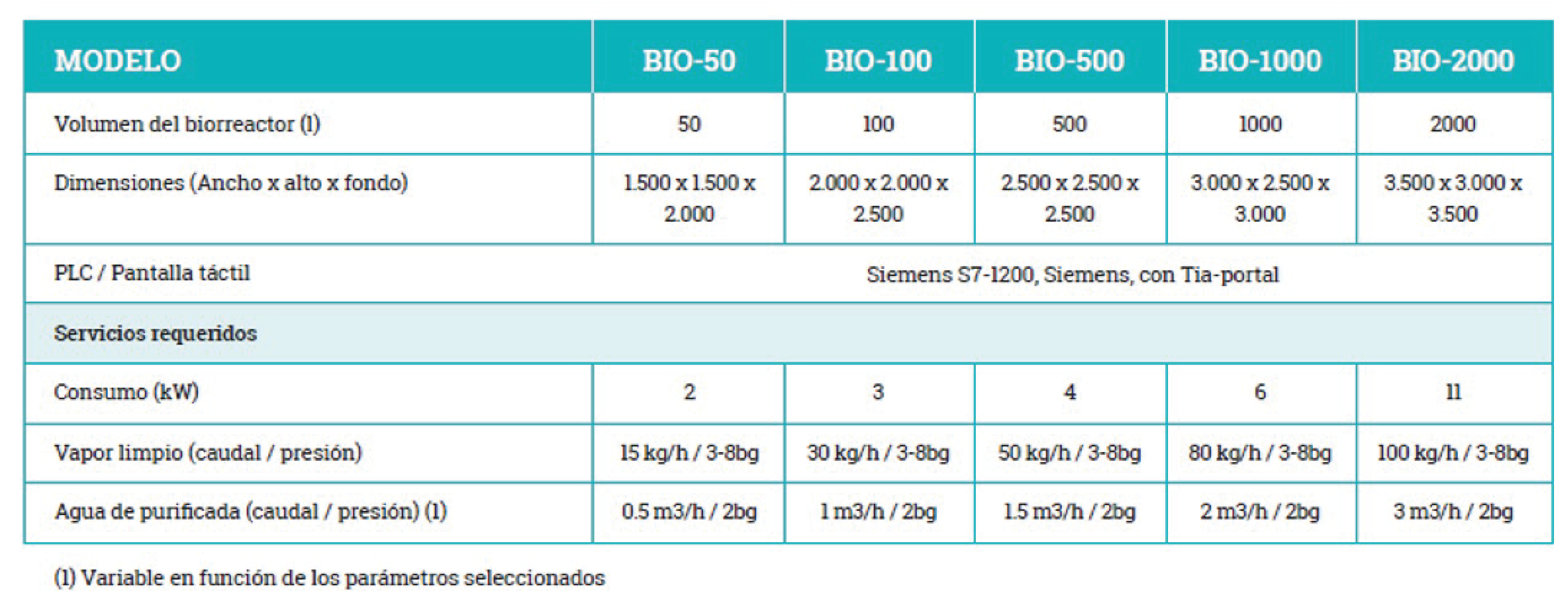

Control systemThe equipment is controlled by a stainless steel control cabinet containing all the components necessary for the operation of the equipment. The standard control system consists of a touch screen HMI computer (SCADA) and a Siemens PLC.

Included documentationOperating/maintenance manual, quality certificates of the components, welding certificates, manuals/data sheets of the components, CE marking, SDS/DQ/FAT protocols executed in our premises.

ADVANTAGES OF OUR DESIGN

- Complete documentation of quality, including SDS, DQ & FAT protocols (IQ-OQ as optional).

- A very versatile control system that allows all options to be custom configured for optimal cultivation conditions.

- High quality equipment, with GMP design and complying with all international standards in force.

- (21 CFR Part 11, GAMP 5, ASME BPE and ISPE recommendations).

- Customised technical advice, adapted to each client.

- Optional customisation and bespoke design.

- High-end components from well-known brands.

- ASME-BPE sanitary fittings and connections.

TECHNICAL SPECIFICATIONS

Request a quote

Request a quote

Blog

Blog

FAQ

FAQ

Contact

Contact